- Products

- Video

- Events

- News

- Landing

- Pages

Comecer offers recently a new system (ALCEO halogen 2.0) for small scale routine production of I-124. In this work we performed optimization and validation of the production process with this new system. Special aim was the increase of the specific activity together with an significant decrease of volume. This was achieved by a new design of the evaporation unit and an optimized degrading foil.

I-124 was produced via the Te-124(p, n)I-124 reaction. The reaction was performed on a PETtrace 860 cyclotron (GE Healthcare, Uppsala, Sweden). With the used set up, beam currents up to 20 μA were possible. For this work beam currents between 10 μA and 15 μA were used.

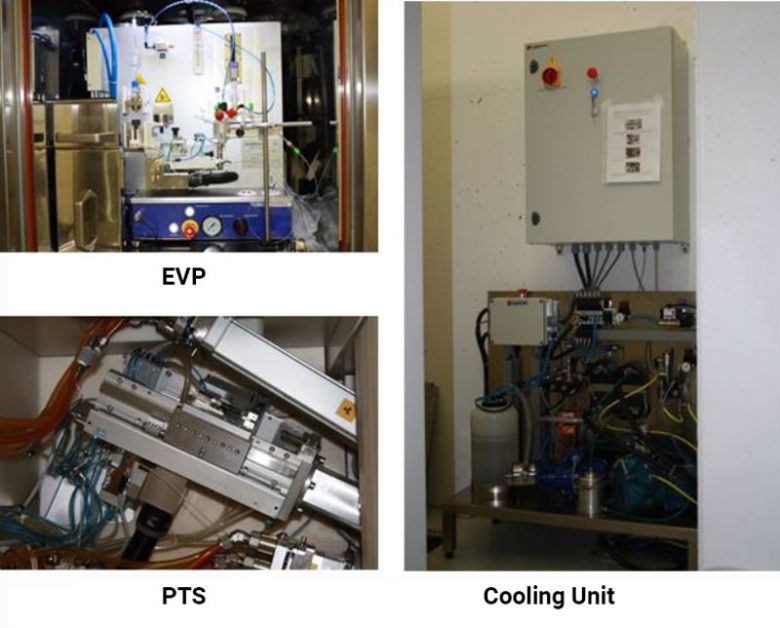

The material for the irradiation was a mixture of 300 mg TeO2 and 15 mg Al2O3. This mixture was sintered into a shuttle for automated handling. Besides the use as a carrier, the shuttle works also as a sealing and supports the cooling of the target material during the irradiation. The Comecer ALCEO Halogen 2.0 itself consist of two different parts. The evaporation unit (EVP) and the irradiation unit (PTS) with a supporting cooling unit.

Figure 1: Components of the Comecer ALCEO Halogen 2.0

The production of I-124 can be separated in three different parts:

Before the first irradiation, the target material must be sintered into the shuttle. For this the target material is mixed with Al2O3 as a superplasticizer and then heat treated for melting and fixing it to the shuttle. Once prepared, the shuttle can be stored under room conditions, best directly in the EVP or in its Hotcell.

For the irradiation, the shuttle is send to the PTS and the cooling is switched on. The parameters for the bombardment, beam current and time, has to be chosen depending on the amount of activity needed. During the bombardment, the EVP can be prepared for the irradiated shuttle.

The Overhaul of the shuttle consist of two parts. First, extraction and trapping of the produced I-124 out of the target, and second, elution of the trapped I-124 into a product vessel.

Due to extract the produced I-124 the shuttle is once more heat treated. The same temperature gradient is also used for the first preparation of the shuttle. I-124 vapor is then trapped in a glass tube pre-coated with 0,05 N NaOH.

The trapped product is finally eluted with 100 μL of 0,05 N NaOH.

Figure 2: Timeline I-124 Production

Six different productions were validated using the same shuttle and target material. Due to several reasons different beam currents and bombardment times were applied. Production data and results are shown in the table and the chart below.

Figure 3: Production data for I-124 left: results and irradiation parameters / right: absolute activity yield and weighted yield [MBq/μAh]

During the production process there is a consumption of the target material. Different approaches was used to determine the life time of the prepared shuttle:

The yield was stable (measured as MBq/μAh) over the performed productions (Figure 3).

Before and after the bombardment, a picture of the shuttle was taken. An additional picture was taken after the overhaul.

The weight of the shuttle was measured before and after the irradiation and also after the overhaul. An average loss of weight of 0,387 mg/production was found.

Figure 5: Loss of weight per production

The activity of the shuttle was measured after the overhaul. Out of this and the product activity an activation coefficient (product activity / activity of the shuttle) was calculated.

Figure 6: Activation coefficient

Thanks to the optimized conditions for irradiation and extraction, I-124 could be produced in good radiochemical yields and high purity in less than 1mL extraction volume for routine applications.

Further work are currently on the way to determine the stability of the prepared shuttle and the number of possible extractions.

Log in to your Comecer Account to download data sheets

Log In Lost PasswordNews and invitations to events and fairs directly in your mailbox

Subscribe