PETswitch Features

Why Choose PETswitch?

Nuclear medicine laboratories face a critical challenge: ensuring the safe and controlled transfer of radioactive targets from cyclotrons to hot cells. PETswitch solves this by providing:

- Maximum operational & safety reliability

Radiation‑resistant components and integrated interlock systems ensure safe operation at all times.

- Universal compatibility

PETswitch works seamlessly with any cyclotron and hot cell model.

- Liquid & gas support

Compatible with both liquid targets (including Ga‑68) and gaseous isotopes.

- User‑friendly interface

The software minimizes errors and speeds up repetitive operations.

- Flexible & scalable

Modular architecture adapts to any layout and easily expands with additional lines or cells.

PETswitch brings precision, reliability, and peace of mind to daily operations.

PETswitch is the only delivery system that combines:

- Universal compatibility, it works with any cyclotron

- Liquid (including Gallium‑68) & gas transfer

- Unlimited multi–hot cell management

- High‑radiation‑resistant components

- Intuitive, customizable software interface

A fully modular solution, designed to grow and evolve with your facility.

How PETswitch Works

PETswitch automates the entire transfer process:

- Configuration

Set up cyclotron‑to‑cell routing from the software interface.

- Automated Switching

Interlocks verify valve states, shielding, and line integrity before every transfer.

- Real-Time Interlock Monitoring

Track the Hotcell Interlock status and automatically stopping the flow in case of anomalies during operation.

- Traceability

Every operation is logged for documentation and GMP support.

Software Features

- Clean, intuitive HMI

- Customizable workflows and recipes

- Role‑based access levels

- Real‑time system diagnostics

- Event logs with export options

Safety & Compliance

- Radiation‑resistant mechanical and pneumatic components

- Interlock systems preventing wrong routing or unsafe conditions

- Leak‑tight, shielded interfaces

- Fail‑safe operation and alarm management

- Documentation to support GMP processes

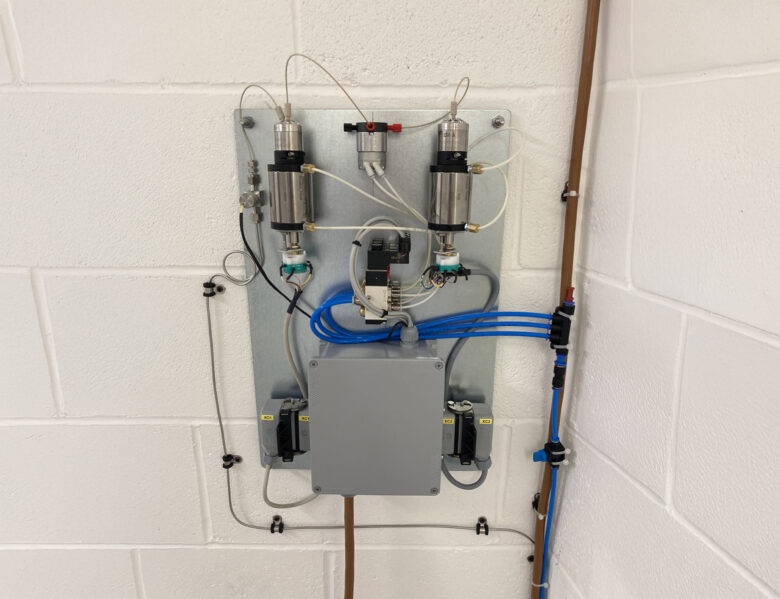

Modular Architecture

PETswitch is built from scalable modules:

- Core manifold with switching valves

- Optional pressure/flow sensor packs

- Industrial PLC/HMI controller

- Expansion modules for additional lines or destinations

The modularity makes PETswitch ideal for new installations or retrofits.

Installation & Support

- Fast commissioning with minimal downtime

- Layout assessment and routing study

- Validation support (IQ/OQ)

- Operator training

- Optional maintenance packages

Frequently Asked PETswitch Questions and their Answers

What is PETswitch used for?

PETswitch is an automated cyclotron target switch designed to route radioactive targets safely and efficiently from any cyclotron to one or multiple hot cells. It ensures controlled, traceable, and reliable target transfer operations.

Is PETswitch compatible with my cyclotron model?

Yes. PETswitch is universally compatible and works with any cyclotron on the market. Its architecture is vendor‑agnostic and adaptable to new installations or retrofits.

Can PETswitch handle both liquids and gases?

Yes. PETswitch supports the transfer of liquid targets (including Gallium‑68) and radioactive gases.

How many hot cells can PETswitch manage?

There is no fixed limit. The system supports multiple hot cells, and facilities can expand routing capabilities thanks to the modular hardware architecture.

What safety features does PETswitch include?

PETswitch integrates several safety mechanisms:

- Radiation‑resistant valves and components

- Interlock systems preventing misrouting or unsafe valve states

- Leak‑tight connections

- Alarm handling and safe‑state fallback

- Full traceability for GMP support

How does PETswitch improve workflow efficiency?

Automation reduces manual steps, minimizes operator errors, shortens processing times, and enables consistent, repeatable transfer operations.

Does PETswitch provide traceability for GMP documentation?

Yes. Every operation is logged, time‑stamped, and available for export, supporting GMP workflows and quality audits.

Can PETswitch be installed in existing laboratories?

Absolutely. PETswitch is suitable for retrofits and new layouts. Its modular structure allows flexible routing in complex or space‑limited environments.

What is required for installation?

Comecer performs a layout assessment, defines a routing plan, installs the hardware, validates the system (IQ/OQ), and trains operators. Installation time is minimized thanks to the modular design.

Does the system include a software interface?

Yes. PETswitch features an intuitive, customizable HMI with:

- Real‑time diagnostics

- User‑role management

- Visual routing configuration

- Event history and export capabilities

Can PETswitch be expanded in the future?

Yes. PETswitch is fully modular and scalable. Additional lines, sensors, or hot cell connections can be added as facility needs evolve.

How long does installation usually take?

The modular design allows fast installation, with minimal downtime. Exact timelines depend on facility layout and number of routing lines.

Does Comecer offer after‑sales support?

Yes. Maintenance plans, remote diagnostics, spare parts, and on‑site technical support are available to ensure long‑term system performance.

Can the software integrate with LIMS or SCADA?

Integration options may be available depending on configuration. APIs or industrial communication protocols can be supported on request.