- Products

- Video

- Events

- News

- Landing

- Pages

ALCEO is a fully automated solid target processing system for the production of radionuclides used in radiopharma. The radionuclides produced are available in a form suitable for radiopharmaceutical synthesis. The integrated system allows all the operations to be carried out without the manual intervention of operators.

The ALCEO series is a family of configurable machines based on various parameters such as:

The radioisotopes that can be produced are 61Cu, 64Cu, 89Zr, 124I, 123I, 68Ga, 44Sc, 86Y and 45Ti.

ALCEO is a fully automated solid target processing system for the production of radionuclides used in radiopharma. The radionuclides produced are available in a form suitable for radiopharmaceutical synthesis. The integrated system allows all the operations to be carried out without the manual intervention of operators.

The ALCEO series is a family of configurable machines based on various parameters such as:

The radioisotopes that can be produced are 61Cu, 64Cu, 89Zr, 124I, 123I, 68Ga, 44Sc, 86Y and 45Ti.

The complete ALCEO configurations feature a single PTS (pneumatic transfer system) and Cooling System unit: the transport of the target to the corresponding module is performed via a target switch.

The radionuclides produced are available in a form suitable for radiopharmaceutical synthesis.

The integrated system allows all the operations to be carried out without the manual intervention of operators.

The ALCEO system is designed for the application of commercial cyclotrons with energy ranging between 5 and 30 Mev.

ALCEO METAL allows the irradiation of a Nickel/Zinc galvanic deposit 64-61Ni/68Zn aimed at obtaining radionuclide 64-61Cu/68Ga.

It consists of two modules for the production of both 64-61Cu/68Ga and one single PTS.

It allows also the irradiation of a sheet of natural Yttrium 89Y and Scandium 45Sc aimed at obtaining radionuclide 89Zr. It consists of two modules for the production of 89Zr and one single PTS.

From today, it’s possible also to work with salts: Alceo allows the irradiation of compressed calcium/Strontium carbonate powder (44Ca/86Sr) aimed at obtaining radionuclide 44Sc & 86Y.

The EXTERNAL PLATING is an independent module of the Alceo Metal system that permits the electro-deposition of isotopes in a separate area. It can perform the following operations automatically deposit of the nickel/zinc to be irradiated inside the target shuttle.

The POWDER COMPRESSING STATION is an independent module of the Alceo Metal system that permits the compressing of salt in a separate area. It can perform the following operations: making the pellet of the calcium/strontium carbonate to be irradiated inside the target shuttle

The target is the component which is directly irradiated by the cyclotron beam: it is an enriched isotopewhich produces the positron emitters after the bombardment.

The Alceo target shuttle allows the automatic positioning of the target (deposition, foil or compressed powder) in front of the cyclotron beam. Once the shuttle has been positioned on the PTS, the target can be bombarded. The shuttle is equipped by a spacial cup wich is functioning as integrated degrader foil.

The irradiation unit is directly connected to the cyclotron and guarantees the correct positioning of the target in front of the beam port. Target positioning is fully automated. The unit is connected to its own “water and helium cooling system”. The cooling system is connected to the cyclotron cold water and helium circuit, as a normal liquid target.

It can be placed inside a hot cell which is connected to the cyclotron by the flexible tube for the target transfer. It is a pneumatic system that carries out automatically the following operations:

Dissolution processes are performed by separated capillares circuits to avoid any kind of cross contamination. Inside the hot cell, 7 different dissolution head will be placed, in order to perform the production of all the isotopes without cross-contamination.

It can be placed inside a hot cell and must be connected to the EDS module by capillary lines. TADDEO-PRF module contains the necessary components for the purification by Ion Chromatography of the produced isotope (64-61Cu/68Ga/89Zr/45Ti/44Sc/86Sr and even more). The module is disposable cassette based.

ALCEO HALOGEN allows the irradiation of a Tellurium oxide deposit 124Te and 123Te to obtain the equivalent radionuclide 124I and 123I.

It consists of a module for the production of 124I and 123I (mixed process) and one single PTS.

The target is the component which is directly irradiated by the cyclotron beam: it is an enriched metal isotope (123Te and 124Te) which produces the positron emitter (123I and 124I) after the bombardment.

The Alceo Halogen target shuttle allows the automatic positioning of the deposit in front of the cyclotron beam. Once the shuttle has been positioned on the PTS, the target can be bombarded.

The irradiation unit is directly connected to the cyclotron and guarantees the correct positioning of the target in front of the beam port. Target positioning is fully automated. The unit is connected to its own “water and helium cooling system”. The cooling system is connected to the cyclotron cold water and helium circuit, as a normal liquid target.

The unit can be placed inside a hot cell and must be connected to the PTS unit with the target transfer tube. The EVP module contains the necessary components for the following operations:

The purification task makes use of a “disposable cassette”, in order to avoid the module contamination. Comecer supplies the cassette, while the preparation of the required synthesis reagents is the customer’s responsibility.

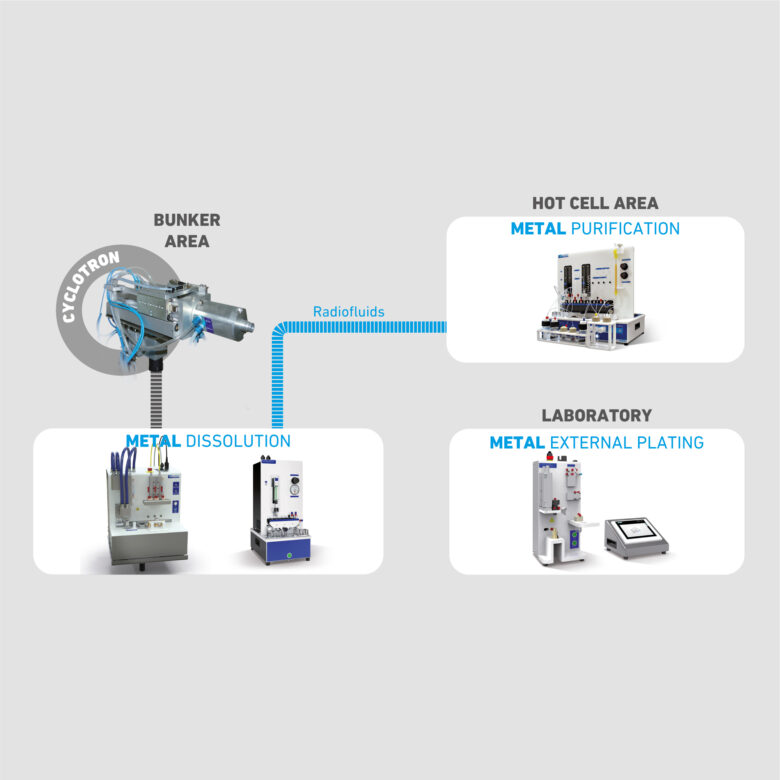

ALCEO METAL RETROFIT is the best solution for a pre-existing laboratory, where hot cells and trenches for capillary passage do not possess the requirements for proper installation of the ALCEO METAL.

ALCEO METAL RETROFIT is based on ‘accessories’ as the standard Alceo Metal, but the dissolution and purification phases are separated in distinct areas. In this configuration, connection between the two areas consists of a single fluid transfer capillary and not of a complex pneumatic transfer system of the target using corrugated pipe. In the fully accessorised configuration, it allows the production of 64Cu, 89Zr, 68Ga.