- Products

- Video

- Events

- News

- Landing

- Pages

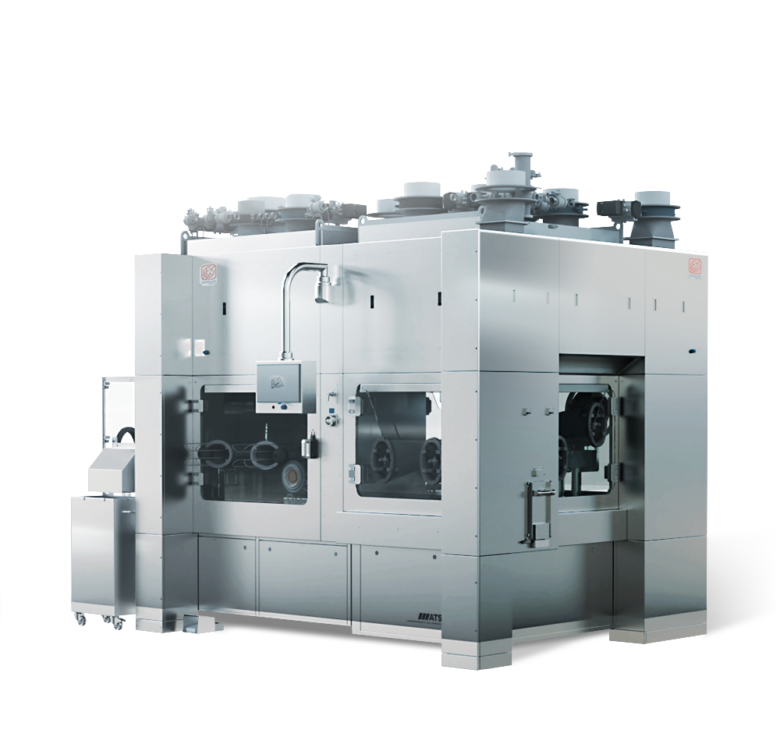

Flex-Line™ is sterile robotic filling machine for ready-to-use vials and syringes, integrated with isolator. Flex-Line™ is suitable for filling ready-to-use (RTU) vials and prefilled syringes (PFS), suitable for R&D operations and pilot-scale sterile production. It’s a combined solution that integrates a robotic nest/tub filling machine and a Class A modular isolator equipped with the laminar flow throughout the entire process, designed to meet the needs of liquid sterile production cycles.

The isolator is a critical component in ensuring the purity and quality of products on an automated filling line. Its meticulous design follows strict cGMP standards and pharmaceutical protocols for handling aseptic materials, ensuring the highest level of quality and safety.

Comecer’s comprehensive package includes an isolator chamber with multi-sided access for easy operation, an advanced ventilation and air filtration system to maintain clean air quality, a state-of-the-art VPHP generator for efficient decontamination, and a specialized VPHP distribution system for even dispersal of the sterilizing agent.

The VPHP generator and the distribution pipes allows the decontamination of the chambers.

The isolator’s performance qualification will consist of the development of a dedicated decontamination cycle with a target of a 6-log microbial reduction.

|

Sterile filling in vials for liquid products |

|

Sterile PFS filling for liquid products |

|

Sterile filling in vials for lyophilized products |

|

VPHP decontamination system |

|

Compact footprint |

|

Suitable for vaccine production |

|

Full Laminar Air Flow |

|

All-in-one isolator integration |

|

Panel PC HMI Control System fully compliant for CFR21 Part11 and Data Integrity requirements |

Flex-Line™ is designed for aseptic filling of Ready-To-Use nested products such as PFS and vials, for R&D and Pilot Scale sterile production.

All isolators chamber air quality are compliant with ISO5 / Grade A (EU-GMP) and equipped with laminar flow over the entire area.

ROBOTIC HANDLING

Thanks to its modular design, the filling line is available with different possible configurations in order to fulfil the requirements of different production needs.

Possibility of filling nested syringes and vials.

Aseptic Filling via perfect combination between machine and isolators. Integrated VPHP decontamination system. Full process control by HMI.

From nest/tubs to filled aseptic vials or pre-filled syringes by semi-automatic or automatic processing. Flex-Line™ is designed to allow minimal human intervention to reduce contamination risk on your aseptic vaccines production process.

Fully automatic or semi-automatic No-Touch-Transfer procedures grant smooth opening and transfer of the tubs inside the process area.

ONE SOLUTION FITS ALL

+

+